Far 2212 swivel Dirt Separator with magnets 1" for thermal systems 2212 1

FRU 2212 1

8052190853258

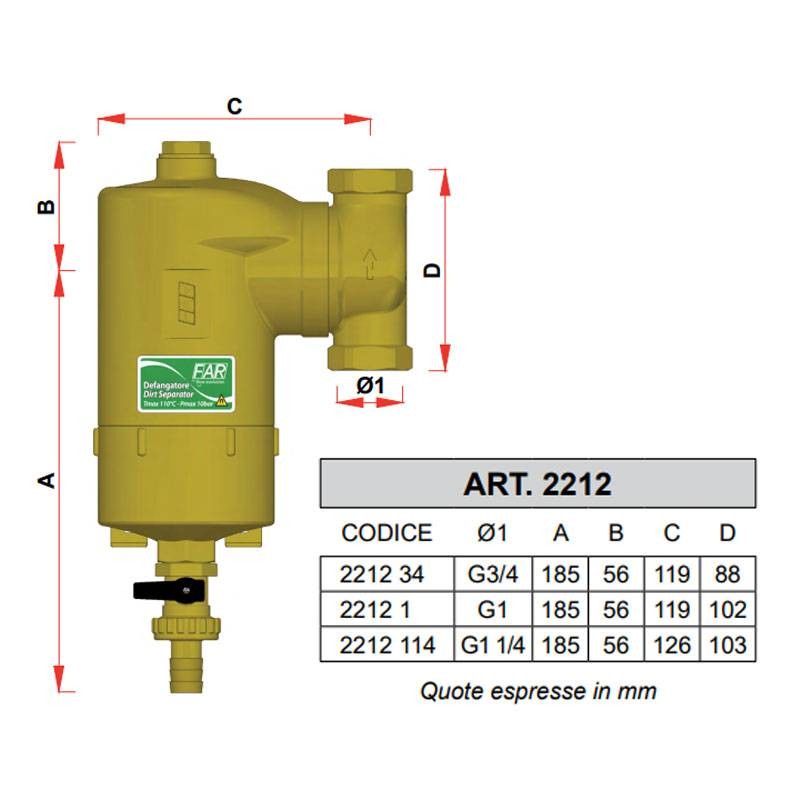

Far 2212 swivel Dirt Separator with magnets for thermal systems for removing ferrous particles:

- Size 1"

- Kv (cubic meters/h) 11.20

- CB753S brass body

- Connections to piping: F-F

- Connection at the top 1/2 with plug

- Drain cock for sludge evacuation

- Pressure rating: 10 bar

- Maximum operating temperature: 110°C

- Removable magnets

- Patented.

Far 2212 swivel Dirt Separator with magnets 1" for thermal systems 2212 1

€151.62

Tax included

€151.62

Far 2212 swivel Dirt Separator with magnets 1" for thermal systems 2212 1

€151.62

Tax included

Tax included

-20€

EXTRA

Add the coupon code in the payment page

Limited-time promotion

Items Available: 3

qty

Far 2212 swivel Dirt Separator with magnets 1" for thermal systems 2212 1

€151.62

Buy it within and receive it from Thursday, 13 November

Pay in installments with Klarna

Pay in installments with KlarnaSPECIFICATION ITEMS:

- Adjustable defangator for heating and cooling systems for removal of ferrous particles, CB753S yellow brass body, 3/4-1 female-female pipe connections, connection at the top 1/2 with plug and possibility of installing an air vent valve, drain cock at the bottom for sludge evacuation, patent pending impurity separation system, removable magnets. Pressure rating 10 bar, maximum operating temperature 110°C.

Features:

- Body: brass CB753S

- Upper stopper: brass CW617N

- Lower tap: brass CW617N

- Max operating temperature: 110°C

- Filter cartridge: Nylon 6FV

- O-Ring: EPDM

- Pressure rating: 10 bar

- Max fluid velocity: 1.4 m/s

Overview:

- The defangator is used to separate impurities from water that are present inside heating and cooling systems to improve heat transfer fluid circulation and heat exchange. Impurities such as rust or welding residues, which are present in the pipes of the distribution network, are collected in a special chamber where, once deposited, they can no longer re-enter the circulation. In the defudger there is a section enlargement where a reduction in fluid velocity occurs. This slowing down allows a decrease in drag force and promotes the fall to the bottom of the impurities by settling. Inside this chamber is a cartridge consisting of vertical bars and placed transverse to the direction of the fluid. To further divert the flow on the vertical bars of the cartridge, there are side fins that slow and stop the particle travel. Sediment settles to the bottom of the chamber and is then removed by opening a drain valve. At the top of the defangator is a threaded connection with a plug where an automatic air vent valve can be installed to facilitate the expulsion of gases, which slowed by the cartridge, rise to the top. The defangator art.2212, equipped with magnets, is particularly suitable for installation on systems where there is a higher concentration of ferrous particles, scale and debris due to corrosion.

Data sheet

- Type: Hydraulic and Dirt Separators, Filters

- Connection: F/F

- Hoses: 1