Savio Inoxdens Moon 25S Methane/LPG Condensing Boiler 10312.1049.0

Savio Inoxdens Moon 25S sealed chamber condensing boiler:

- Heat output 24kW

- Adaptive Gas Methane/LPG Technology

- Energy class A+

- Modulation 1:9

- For heating and domestic water

Savio Inoxdens Moon 25S Methane/LPG Condensing Boiler 10312.1049.0

Savio Inoxdens Moon 25S Methane/LPG Condensing Boiler 10312.1049.0

Tax included

-20€

EXTRA

Add the coupon code in the payment page

Savio Inoxdens Moon 25S Methane/LPG Condensing Boiler 10312.1049.0

Pay in installments with Klarna

Pay in installments with KlarnaFrequently bought together

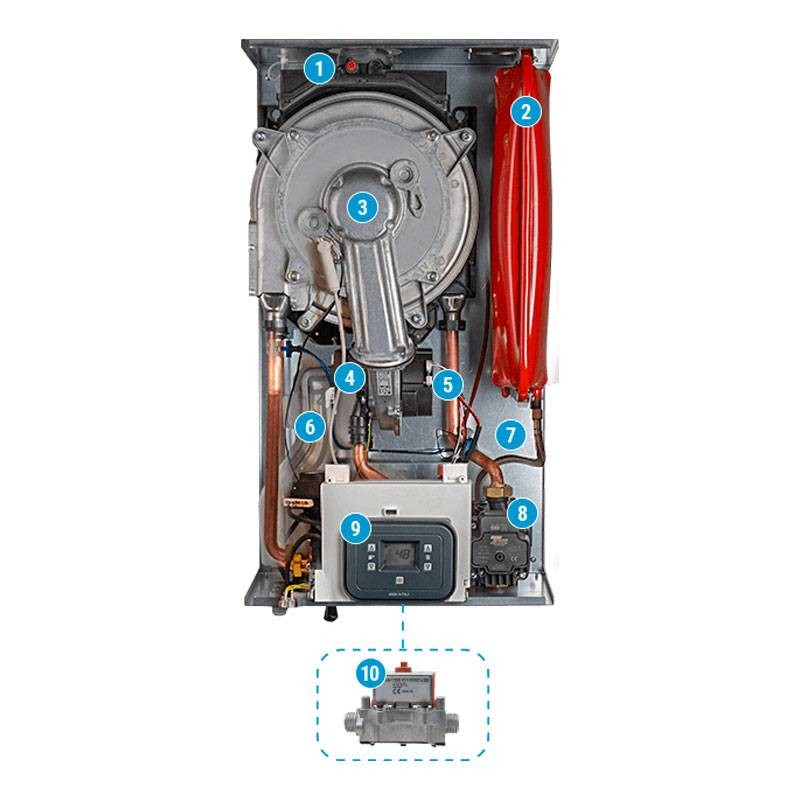

The InoxDens Moon condensing boiler, unlike traditional boilers, allows energy recovery by condensing the water vapor contained in the flue gas; that is, for the same amount of heat produced, it consumes less gas and, in addition, the flue gas contains fewer substances harmful to the environment. Its materials and control systems provide safety, high comfort and energy savings, so that the advantages of self-contained heating can be fully appreciated.

Advantages:

Adaptive Gas technology less consumption, more efficiency, less emissions:

- The innovative Adaptive Gas technology, with which all models in the InoxDens line are equipped, allows boilers to adapt in complete autonomy to different types and qualities of gas. The electrode, in addition to detecting the flame, also detects the characteristics of the gas and automatically adapts combustion parameters to maintain the highest level of efficiency, resulting in reduced consumption and emissions compared to traditional control systems. The Adaptive Gas system makes the boiler ready to operate with any type of gas without transformations.

InoxDens Moon is SAVIO's new range of wall-hung condensing boilers. Excellent performance and high efficiencies that last over time thanks to the innovative heat exchanger. Easy operation thanks to the digital control panel with display designed to communicate with the user easily and conveniently.

- Boiler with single-circuit stainless steel primary exchanger, free of joints and/or welds, which maintains high efficiency even on older systems

- New combustion system with patented gas-adaptive technology (Advanced Adaptive Gas Combustion Control A²GC²) The electronics continuously analyzes combustion (CO2) through the flame signal and takes action by acting on the gas valve and fan to allow proper combustion under all conditions of use. The electronics make it easy to adapt the boiler to various types of gas without having to intervene with mechanical transformation kits

- Instantaneous production of domestic hot water with dedicated plate heat exchanger

- Sanitary preheating function: faster delivery of domestic hot water

- User interface with display and multifunction keys for adjustment and parameter setting

- Easily inspectable by-pass as standard

- Chimney Protection System: electronic management of flue gas overtemperatures, ensuring maximum protection of the chimney

- Intubation on flues: particularly suitable for operation in flues that require intubation with high pressure drops

- Minimal pollutant emissions (class VI - EN 15502-1)

- Sliding temperature operation via optional outdoor probe

- Low-consumption modulating heating circulator (ErP Ready - Class A)

- Three-attempt digital flame control in the event of blocked operation due to lack of flame detection (natural gas configuration)

- Three-piece removable casing for easier maintenance or inspection

- For SV versions: possibility of setting the maximum power output to the external boiler

The heat exchanger consists of a combustion chamber, condensation zone and an insulated metal disc protected with silicone ceramic fiber separating the two areas. By using a single stainless steel strip to produce the coil, including inlet/outlet connections, the following advantages are achieved:

- Accumulation of dirt and debris is avoided

- The water flow rate is evenly distributed and ensures even heat exchange

- Water flow rate is constant for longer product life

- Reduced pressure drop with optimized circuit

The ease of cleaning and robustness of such an exchanger is one of the main strengths of the product since it can be used on new systems but also on old systems in case of renovations.

Features:

- Nominal heating/sanitary heat flow kW 21.0 / 26.0

- Minimum heating/sanitary flow rate kW 3.0 / 3.0

- Maximum heating/sanitary output 60°/80°C kW 20.7 / 25.6

- Minimum heating/sanitary output 60°/80°C kW 2.8 / 2.8

- Maximum heating/sanitary output 30°/50°C kW 22.8 / 28.2

- Minimum heating/sanitary output 30°/50°C kW 3.2 / 3.2

- Quantity of condensate at Q.nom. 30°/50°C (in heating) l/h 4.2

- Quantity of condensate at Q.min. 30°/50°C (in heating) l/h 0.5

- Condensate pH 4.0

- Efficiency nom. 60°/80°C % 98.4

- Yield min. 60°/80°C % 94.0

- Yield nom. 30°/50°C % 108.6

- Yield min. 30°/50°C % 105.2

- Yield at 30 % load % 109.8

- Energy efficiency ?s % 94

- Thermal losses at stack with burner in operation Pf (%) 1.3

- Thermal losses to stack with burner off ?T 50°C Pfbs (%) 0.2

- Thermal losses to the environment through the casing with burner operating Pd (%) 0.3

- NOx class No. 6

- Minimum/maximum heating temperature °C 25 / 80

- Minimum/maximum heating pressure bar 0.3 / 3

- Available heating head (at 1000 l/h) mbar 340

- Expansion tank capacity liters 7

- Minimum/maximum sanitary temperature °C 35 / 55

- Minimum/maximum sanitary pressure bar 0.3 / 10

- Maximum flow rate (?T=25 K) / (?T=35 K) l/min 15.4 / 10.7

- Specific sanitary flow rate (?T=30 K) l/min 12.8

- Voltage/Power at rated heat flow V~/ W 230 / 100

- Power at minimum heat flow rate W 12

- Power at idle (stand-by) W 3

- Degree of protection No. IPX5D

- Minimum/maximum flue gas temperature °C 38 / 78

- Minimum/maximum flue gas mass flow rate kg/s 0.0014 / 0.0121

- Minimum/maximum air mass flow rate kg/s 0.0013 / 0.0116

- Max coaxial flue exhaust length (Ø 60/100 mm / Ø 80/125 mm) m 10 / 12

- Max length of split flue exhaust (Ø 80+80 mm) m 40

- Dimensions: Height x Width x Depth mm 700 x 400 x 300

- Weight kg 31.5

- Boiler water content l 2.0

Data sheet

- Type: Boilers

- Model: Natural gas/LPG

- Thermal power: 24 kW

- Energy class: A+

- Series: Inoxdens Moon 25S